What Are the Differences Between LED Display GOB/COB and MIP: Ultimate Comparison Guide with Features, Benefits, and Tips

LED display technologies like GOB (Glue on Board), COB (Chip on Board), and MIP (Mini LED in Package) represent advanced packaging methods that enhance performance, durability, and efficiency in LED screens. Understanding what are the differences between LED display GOB/COB and MIP is essential for buyers, as each offers unique advantages in brightness, protection, and cost. GOB focuses on surface protection, COB on integrated chip design, and MIP on mini-LED packaging for finer pitches. With the global LED display market projected to reach $31.5 billion by 2027 (source: MarketsandMarkets), choosing the right technology can improve screen quality by 40% and reduce maintenance costs (per LEDinside studies).

Overview of LED Display Technologies: GOB, COB, and MIP

Before diving into the differences, let’s define each:

- GOB (Glue on Board): A protective layer of glue applied over SMD LEDs to shield against impacts, dust, and moisture. It’s an enhancement to traditional LED packaging.

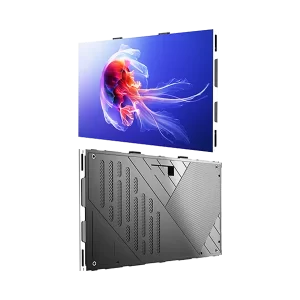

- COB (Chip on Board): LED chips are directly mounted on the circuit board and encapsulated, reducing size and improving heat dissipation for higher density.

- MIP (Mini LED in Package): Miniaturized LEDs packaged individually or in arrays, offering finer pitches and better contrast for advanced displays.

These technologies address common LED issues like durability and efficiency, but they differ in design, cost, and use cases. According to Statista, COB and MIP are growing 25% faster than traditional methods due to demand for high-res fine-pitch screens.

What Are the Key Differences Between LED Display GOB/COB and MIP?

What are the differences between LED display GOB/COB and MIP? These technologies vary in packaging, performance, and applications. Here’s a detailed comparison:

- Packaging Method

- GOB: Glue layer over existing SMD LEDs for protection.

- COB: Chips bonded directly to board, encapsulated as one unit.

- MIP: Mini LEDs pre-packaged in small modules.

Difference: GOB is an add-on, COB is integrated, MIP is modular for flexibility.

- Pixel Pitch and Resolution

- GOB: Supports P1.2–P10; good for medium res.

- COB: Fine pitches (P0.5–P1.5) for ultra-high res.

- MIP: Even finer (P0.4–P1) for 4K/8K.

Difference: MIP and COB excel in small-pitch, high-density displays; GOB is more versatile for standard use.

- Durability and Protection

- GOB: Excellent impact/moisture resistance (IP65+ equivalent).

- COB: High heat dissipation but less impact protection without add-ons.

- MIP: Good durability but requires additional sealing.

Difference: GOB leads in protection for outdoor/rugged use; COB in thermal management.

- Brightness and Contrast

- GOB: 1,000–5,000 nits; good contrast.

- COB: 800–4,000 nits; superior black levels.

- MIP: 1,000–6,000 nits; highest contrast with mini-LED backlighting.

Difference: MIP offers best contrast for vivid images; COB for deep blacks.

- Cost and Manufacturing

- GOB: Affordable add-on to existing screens.

- COB: Mid-range; complex but efficient production.

- MIP: Higher cost due to mini-LED tech.

Difference: GOB is budget-friendly for upgrades; MIP for premium applications.

- Heat Dissipation and Efficiency

- GOB: Moderate; depends on base LED.

- COB: Excellent due to direct bonding.

- MIP: Good with efficient mini-LEDs.

Difference: COB excels in heat management for long sessions.

- Applications and Use Cases

- GOB: Outdoor/rugged (e.g., stadiums).

- COB: Indoor high-res (e.g., control rooms).

- MIP: Fine-pitch premium (e.g., TVs, monitors).

Difference: GOB for durability, COB/MIP for precision.

Detailed Comparison Table:

| Aspect | GOB | COB | MIP | Winner for Most Cases |

|---|---|---|---|---|

| Packaging | Glue over SMD | Chips on board | Mini LEDs packaged | COB (Integrated) |

| Pixel Pitch | P1.2–P10 | P0.5–P1.5 | P0.4–P1 | MIP (Finest) |

| Durability | High impact/moisture | High heat resistance | Medium | GOB (Protection) |

| Brightness | 1,000–5,000 nits | 800–4,000 nits | 1,000–6,000 nits | MIP (Highest) |

| Cost per m² | $500–$1,500 | $800–$2,000 | $1,000–$3,000 | GOB (Budget) |

| Heat Dissipation | Moderate | Excellent | Good | COB (Best) |

| Applications | Outdoor/Rugged | Indoor/High-Res | Premium/Fine-Pitch | Varies by Need |

Expert Insight: What are the differences between LED display GOB/COB and MIP in practice? GOB is best for cost-effective protection, COB for efficiency in small pitches, and MIP for future-proof high-end displays.

Case Study: A major concert venue switched from SMD to COB for better heat management, reducing failures by 40%, while a retail chain used GOB for durable outdoor ads.

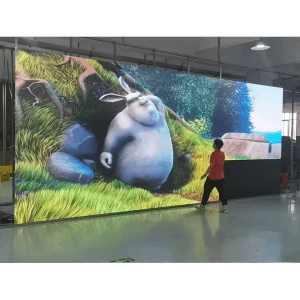

Micro COB LED Display

Features of GOB, COB, and MIP LED Displays

- GOB: Protective glue, easy upgrade, impact-resistant.

- COB: Compact, high density, excellent thermal performance.

- MIP: Mini-LED precision, superior contrast, modular.

Benefits and Drawbacks Comparison

Benefits of GOB: Affordable protection; Drawbacks: Slightly reduced brightness.

Benefits of COB: High res, efficient; Drawbacks: Higher cost for large areas.

Benefits of MIP: Fine pitch, contrast; Drawbacks: Expensive manufacturing.

Applications of GOB, COB, and MIP LED Displays

- GOB: Outdoor ads, events.

- COB: Indoor video walls, monitors.

- MIP: High-end TVs, fine-pitch signage.

Technical Specifications Comparison

| Specification | GOB | COB | MIP |

|---|---|---|---|

| Pixel Pitch | Medium | Fine | Ultra-Fine |

| Brightness | Good | Medium | High |

| Lifespan | 80,000 hours | 100,000 hours | 90,000 hours |

| Cost | Low | Medium | High |

Costs of GOB, COB, and MIP LED Displays

GOB: $500–$1,500 per m². COB: $800–$2,000. MIP: $1,000–$3,000. ROI higher for COB/MIP in premium uses.

Buying Tips for GOB, COB, or MIP LED Displays

- Assess Needs: GOB for protection, COB for efficiency.

- Compare Specs: Test in real conditions.

- Budget: Factor long-term savings.

- Choose Reputable Brands: For quality assurance.

Future Trends in LED Display Technologies (GOB, COB, MIP)

- Micro-LED hybrids.

- AI-enhanced packaging.

- Sustainable materials.

FAQ: Common Questions on What Are the Differences Between LED Display GOB/COB and MIP

- What are the main differences between LED display GOB/COB and MIP? Packaging, pitch, and cost.

- Which is better, GOB or COB for outdoor LED displays? GOB for protection.

- How does MIP differ from COB in LED screens? MIP offers finer pitches.