What Is the Difference Between MIP and COB LED: Ultimate Comparison Guide with Features, Benefits, Costs, and Applications

LED technologies like MIP (Micro LED in Package) and COB (Chip on Board) are revolutionizing displays and lighting with their efficiency and performance. Understanding what is the difference between MIP and COB LED is crucial for choosing the right type, as MIP focuses on micro-scale packaging for high-density applications, while COB integrates chips directly on the board for compactness and heat management. With the global LED market projected to reach $100 billion by 2027 (source: MarketsandMarkets), knowing these differences can help in selecting optimal solutions for screens, lighting, or automotive uses, potentially improving efficiency by 30% (per LEDinside studies).

What Is MIP LED?

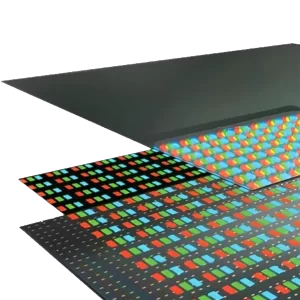

MIP (Micro LED in Package) is a technology where micro-sized LEDs are individually packaged and assembled into arrays, offering ultra-high resolution and brightness for displays. MIP LEDs are small (under 100 microns), enabling fine pitches (P0.4–P1) for 4K/8K screens. They are used in premium TVs, monitors, and wearables, with advantages in contrast and efficiency.

What Is COB LED?

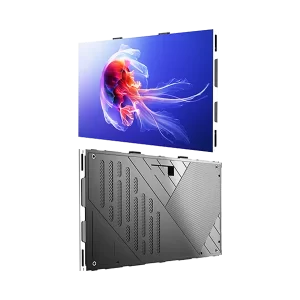

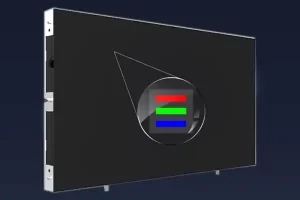

COB (Chip on Board) LED involves mounting multiple LED chips directly on a circuit board, covered with phosphor for light emission. This creates a compact, high-lumen module ideal for lighting and displays. COB is known for excellent heat dissipation and uniform light, used in spotlights, downlights, and LED screens with pitches P0.5–P2.

What Is the Key Difference Between MIP and COB LED?

What is the difference between MIP and COB LED? These technologies differ in design, performance, and use cases. Here’s a detailed comparison:

- Packaging Method

- MIP: Micro LEDs packaged individually or in small groups, allowing for precise assembly.

- COB: Multiple chips bonded directly to the board and encapsulated as one unit.

Difference: MIP is modular and scalable for high-density setups; COB is more integrated and compact, reducing the number of components.

- Pixel Pitch and Resolution

- MIP: Supports ultra-fine pitches (<P1), ideal for high-res 4K/8K displays.

- COB: Medium pitches (P0.5–P2), suitable for standard high-res but not as fine as MIP.

Difference: MIP excels in mini/micro-LED applications for sharper images; COB is better for balanced resolution in larger formats.

- Brightness and Efficiency

- MIP: High brightness (1,000–6,000 nits) with excellent energy efficiency due to micro-size.

- COB: Medium-high brightness (800–4,000 nits) with superior thermal efficiency.

Difference: MIP offers better overall luminosity for displays; COB provides efficient heat management for lighting, reducing energy loss by 20-30%.

- Cost and Manufacturing

- MIP: Higher cost due to complex micro-packaging and assembly.

- COB: Lower cost with simpler production processes.

Difference: COB is more budget-friendly for mass production; MIP is premium for advanced tech, often 50-100% more expensive.

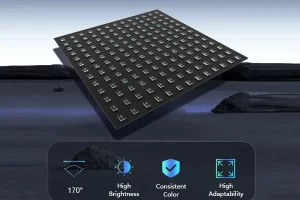

- Durability and Heat Dissipation

- MIP: Good durability but requires careful handling due to micro components; moderate heat.

- COB: Excellent heat dissipation and robustness, as chips are directly on the board.

Difference: COB is superior for high-heat environments like spotlights; MIP needs additional cooling for large displays.

- Applications and Use Cases

- MIP: High-end displays, AR/VR, fine-pitch screens.

- COB: General lighting, automotive, mid-res displays.

Difference: MIP for cutting-edge, high-density uses; COB for versatile, cost-effective applications.

- Power Consumption and Lifespan

- MIP: Low power with long lifespan (90,000 hours) due to efficient micro-LEDs.

- COB: Very low power with excellent lifespan (100,000 hours) thanks to heat management.

Difference: COB edges out in longevity for continuous use; MIP in efficiency for portable devices.

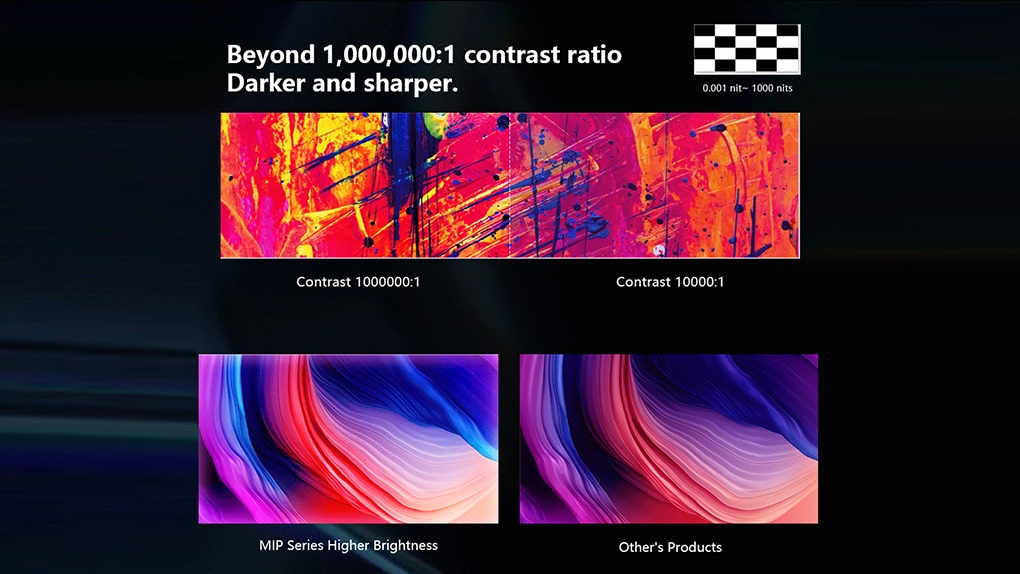

- Contrast and Color Performance

- MIP: Superior contrast with individual pixel control.

- COB: Good uniform color but less precise.

Difference: MIP for premium visual quality; COB for consistent lighting.

Detailed Comparison Table:

| Aspect | MIP LED | COB LED | Key Difference | Winner |

|---|---|---|---|---|

| Packaging | Individual micro packages | Chips on board | MIP modular, COB integrated | COB (Simplicity) |

| Pixel Pitch | Ultra-fine (<P1) | Medium (P0.5–P2) | MIP finer for res | MIP (Resolution) |

| Brightness | High (1,000–6,000 nits) | Medium-High (800–4,000 nits) | MIP higher peak | MIP |

| Cost per m² | $1,000–$3,000 | $800–$2,000 | MIP premium | COB (Affordability) |

| Heat Dissipation | Good | Excellent | COB better thermal | COB |

| Durability | Medium (Delicate) | High (Robust) | COB more rugged | COB |

| Power Efficiency | High | Very High | Similar, COB edges in heat | COB |

| Applications | Premium Displays/AR | Lighting/Mid-Res Screens | MIP advanced, COB versatile | Depends on Use |

| Lifespan | 90,000 hours | 100,000 hours | COB longer | COB |

Expert Insight: What is the difference between MIP and COB LED in practice? MIP is ideal for next-gen displays like 8K TVs due to its precision, while COB shines in efficient lighting like automotive headlights, where heat management is key.

Case Study: LG’s MIP-based TVs offer stunning contrast for home entertainment, while COB LEDs in Philips spotlights reduce energy use by 25% in commercial settings, showcasing their respective strengths.

Features of MIP and COB LEDs

- MIP Features: Micro size for high density, excellent color gamut, modular assembly for repairs.

- COB Features: Compact form, uniform light distribution, superior thermal conductivity, easy integration.

Benefits and Drawbacks of MIP vs. COB LED

Benefits of MIP: Ultra-high res, bright, efficient for small devices; Drawbacks: Expensive, complex manufacturing.

Benefits of COB: Affordable, durable, great heat management; Drawbacks: Limited to medium pitches, less flexible for ultra-fine res.

Overall, MIP is future-oriented for displays, while COB is practical for current lighting needs.

Applications of MIP and COB LEDs

- MIP Applications: High-end TVs (e.g., Samsung’s Micro LED), AR glasses, fine-pitch video walls for control rooms.

- COB Applications: LED bulbs, automotive headlights, indoor lighting, mid-res displays for events.

Example: MIP in Apple’s rumored AR devices for precise visuals; COB in Philips Hue bulbs for efficient home lighting.

Technical Specifications Comparison of MIP and COB LED

| Specification | MIP | COB | Notes |

|---|---|---|---|

| Chip Size | <100 microns | 100-500 microns | MIP smaller for density |

| Brightness | High | Medium-High | MIP for displays |

| Efficiency (lm/W) | 150–200 | 100–150 | MIP more efficient |

| Heat Output | Low | Very Low | COB better dissipation |

| Cost | High | Low | COB economical |

| Lifespan | 90,000 hours | 100,000 hours | COB longer |

| Applications | Displays/AR | Lighting/Screens | MIP premium |

Costs of MIP and COB LED Technologies

- MIP Cost: $1,000–$3,000 per m² for displays; higher due to micro-tech (20-50% more than COB).

- COB Cost: $800–$2,000 per m²; affordable for mass production.

- Factors: Scale, brand, customization add 10-30%. ROI: MIP in high-end (recoup in 1-2 years via premium sales); COB in general use (faster ROI due to low cost).

Tip: For budgets, start with COB; for cutting-edge, invest in MIP.

Buying Tips: Choosing Between MIP and COB LED

- Define Use: MIP for res, COB for efficiency.

- Compare Specs: Test brightness/heat.

- Budget Analysis: Calculate long-term savings.

- Check Brands: Samsung for MIP, Cree for COB.

- Read Reviews: For real-world performance.

Future Trends in MIP and COB LED Technologies

- MIP: Micro-LED for foldable displays.

- COB: Smart lighting with IoT.

- Hybrids: Combining for versatile apps.

FAQ: Common Questions on What Is the Difference Between MIP and COB LED

- What is the main difference between MIP and COB LED? Packaging and pitch: MIP micro, COB integrated.

- Which is better for LED displays, MIP or COB? MIP for high-res, COB for cost-efficiency.

- How does cost differ between MIP and COB LED? MIP 50% higher for advanced features.