How to Identify Good and Bad LED Chips

Introduction

Understanding how to differentiate between high-quality and low-quality LED chips is crucial for ensuring optimal performance and longevity of LED displays and lighting solutions. Here’s a guide on how to assess the quality of LED chips.

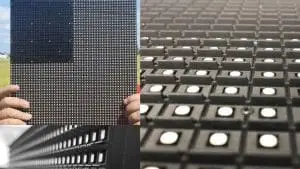

Inspect the Solder Joints

- SMT Paste Process Regular LED light strips are manufactured using the Surface Mount Technology (SMT) paste process, involving solder paste and reflow soldering. High-quality solder joints indicate precise manufacturing and reliable connections.

Evaluate the Quality of the FPC

- Deposited Copper vs Rolled Copper Flexible Printed Circuits (FPCs) come in two types: deposited copper and rolled copper. Deposited copper FPCs have a copper foil that is often protruding and can be identified through close inspection of the solder pads and FPC connections. Rolled copper is smoother and typically indicates a higher quality product.

Assess Surface Cleanliness

- Surface Condition LED light strips produced through the SMT process should exhibit excellent surface cleanliness. There should be no visible impurities or stains, indicating a clean manufacturing environment and meticulous quality control procedures.

Chip Quality and Production Processes

- Visual Inspection Limitations The quality of the LED chips and the production processes cannot be fully assessed through visual inspection alone. Professional evaluation tools and methods are necessary to accurately gauge the performance of the chips.

Use Aging and Testing Equipment

- Aging Test To determine the quality of LED chips, it is recommended to use aging testers with high current loads. Age several manufacturers’ LEDs for at least 24 hours, then measure the brightness to identify which ones show the least attenuation of luminous intensity. The manufacturer with the least attenuation typically signifies the highest quality.

Additional Considerations

- Brightness and Color Consistency High-quality LED chips should maintain consistent brightness and color throughout their lifespan. Variations in brightness or color can indicate poor chip quality or inconsistent production processes.

- Thermal Management Effective thermal management is crucial for the longevity of LED chips. Look for LED displays that incorporate advanced heat sink designs and materials to ensure proper heat dissipation and prevent overheating.

- Electrostatic Discharge (ESD) Protection LED chips are susceptible to damage from electrostatic discharge. Ensure that the chips have built-in ESD protection to prevent premature failure.

Conclusion

- Investment in Quality Identifying high-quality LED chips is essential for achieving optimal performance and durability in LED applications. By following these guidelines and investing in reputable brands, you can ensure your LED displays and lighting solutions perform reliably over time.